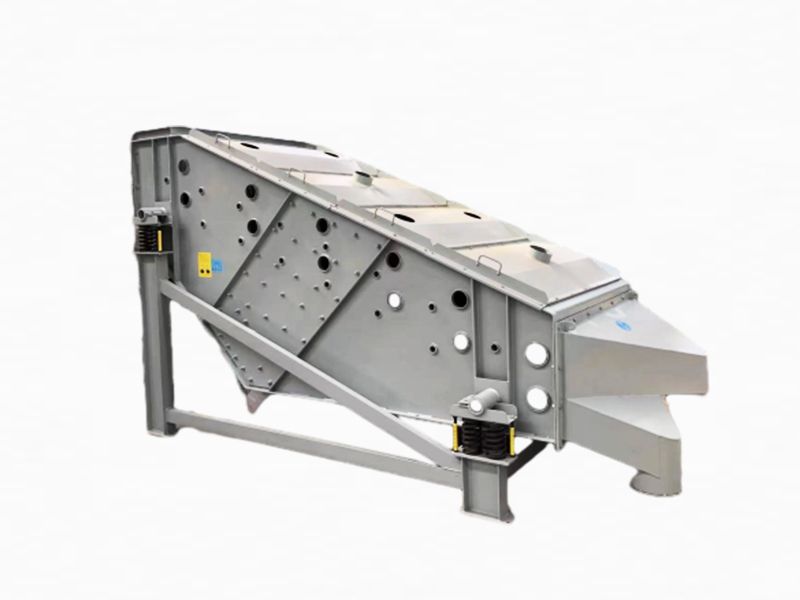

ZYFY series square swing screen, also known as reciprocating screen, fine shaking screen, a multi-purpose new screening equipment, its new design concept and unique structure, make it close to the manual screening of the screening machine, the achievement of the square swing screen nearly perfect screening effect. From the point of view of the running track, the square swinging screen is a nonlinear inertial vibration

Because of the unique structure and working principle of the screen, the square swinging screen is especially suitable for small and large volume classification. ZYFY series square swing screen is a high-precision and high-efficiency screening equipment, which perfectly solves the problem that traditional screening equipment pursues high precision at the expense of production, and the pursuit of large output forces the screening accuracy to decline. The square swinging screen is a completely closed structure, there is no material dust spillover phenomenon.

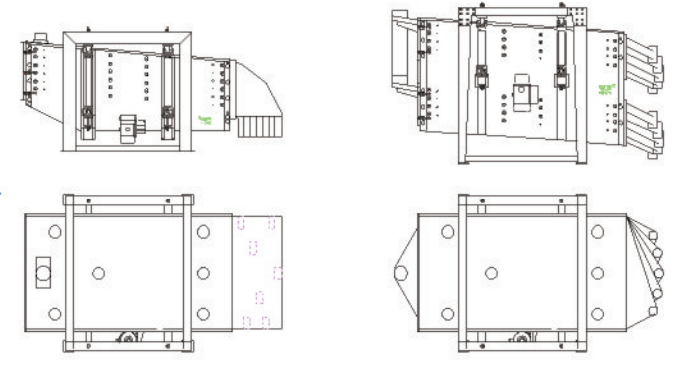

Structure diagram

Working principle

The working principle of ZYFY series square swinging screen is that after the screen machine starts, the screen machine shaking body that is the screen box moves in a circular reciprocating motion under the action of inertial force, the screen box drives the screen surface to shake periodically, so that the material on the screen surface with the screen box makes a plane circular movement, during which, the material less than the screen surface aperture falls to the lower layer through the screen hole and becomes the material under the screen. The material larger than the size of the screen surface is discharged from the discharge port after continuous tumbling and jumping movement to complete the screening work.

Performance characteristics

1, large processing capacity, up to 5 times the output per unit area.

2, exquisite design, unique structure, effective 7-stage separation, screening accuracy of up to 90-95%.

3, the configuration of cleaning screen device, screen is not blocked.

4, low frequency, small load, parts life increased by 5-10 times.

5, simple installation, convenient maintenance, 20 minutes to complete the net change, noise<75 dB.

6, the whole is completely closed, no dust pollution

Applicable industry

Chemical, food, sugar, ceramics, mining, metallurgy, feed, medicine, building materials, mining, grain, paper and other industries of large processing capacity of particles sorting, with irreplaceable advanced and effective screening capabilities.

Classic application industry

Dolomite, quartz sand, urea, soda ash, fracturing sand, PVC slice, salt, ceramics, refractory materials, etc.

Technical parameter

| Model number | Screening area (㎡) | Screening area (㎡) | Number of floors | Turning frequency (r/min) | straining box travel (mm) | power(KW) | Overall dimension(mm) | ||||

| monolayer | recombination | Length | width | height | |||||||

| monolayer | recombination | ||||||||||

| 1036 | 3.6 | 3—8 | 1-10 | 180-260 | 25-60 | 2.2 | - | 4450 | 1700 | 1920 | - |

| 1236 | 4.32 | 180-260 | 25-60 | 3 | - | 4450 | 1900 | 1920 | - | ||

| 1536 | 5.4 | 180-260 | 25-60 | 5.5 | 7.5 | 4450 | 2200 | 1920 | 2750 | ||

| 1836 | 6.48 | 180-260 | 25-60 | 7.5 | 11 | 4450 | 1500 | 2300 | 2750 | ||

| 2036 | 7.2 | 180-260 | 25-60 | 11 | 15 | 4450 | 2700 | 2300 | 2750 | ||

Photograph of the scene